REDUCED BURN WELD THROUGH PRIMER

THIS PRODUCT IS NOW DISCONTINUED PLEASE SEE ARMAWELD – WELDABLE PRIMER CLICK HERE

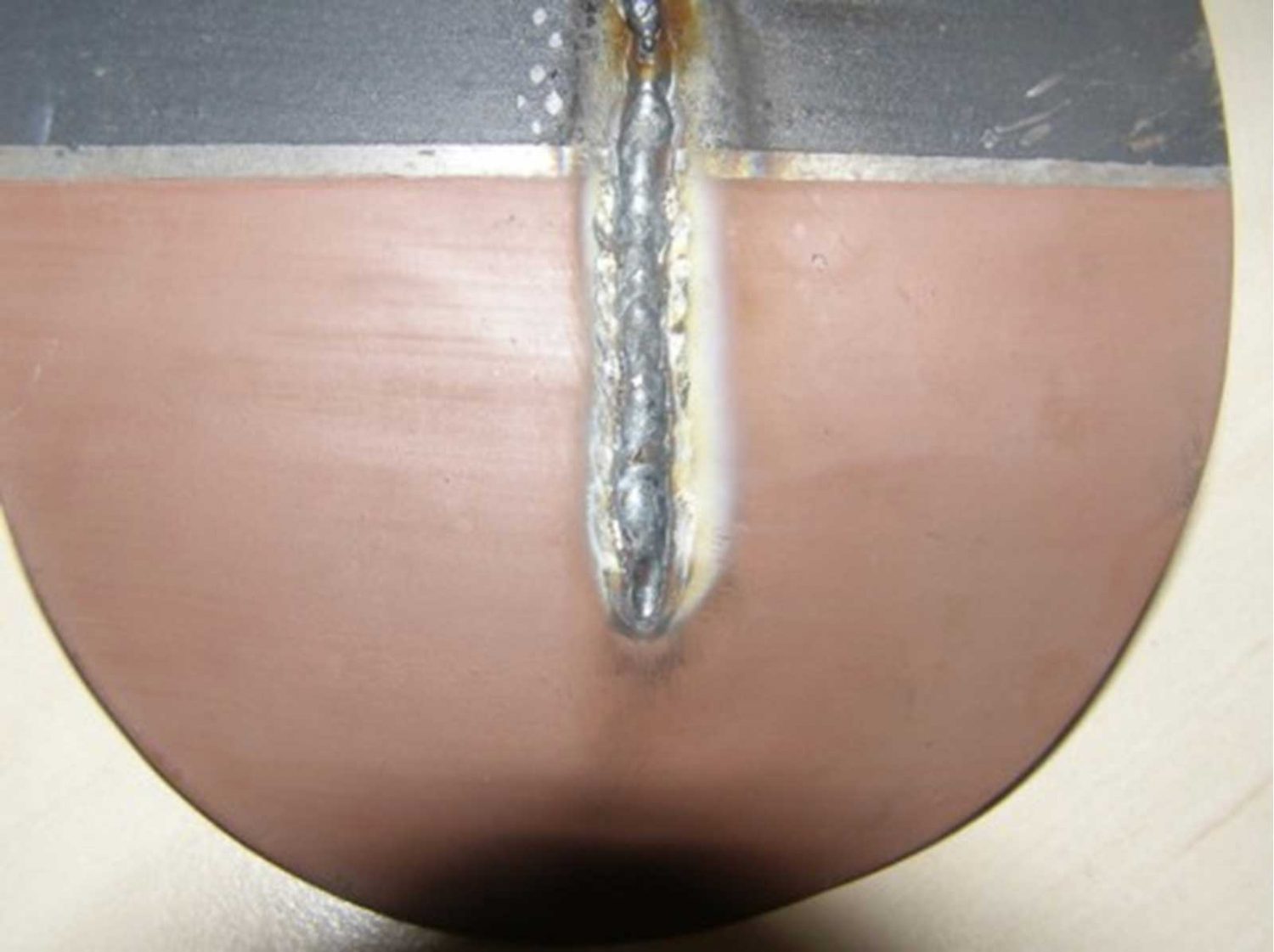

Rustbuster Weld-Thru Primer is a fast-drying anti-corrosion pre-fabrication primer. This two-pack modified zinc silicate shop primer is designed to be fully weldable and cuttable. When welding new steel to the steel coated with Weld-Thru Primer, the weld will have better penetration with the minimum amount of burn back.

- Can be sprayed or brushed.

- Fast drying – touch dry and ready to weld in approx. 6 minutes at 20c.

- Will not give off harmful fumes during welding.

- Suitable for MIG, TIG and MAG/G-FCAW welding.

- Minimum burn back: 50% less burn back than our previous weld through primer.

Prime as you build with Rustbuster Weld-Thru Primer

On certain fabrications you will have to build from the inside, such as when an inner sill is fitted before the outer sill can be welded on. This scenario is perfect for our Weld-Thru Primer, as the weld can be cleaned and coated before the application of the outer sill panel. The primer will help to prevent corrosion, but we also recommend injecting the sill with cavity wax once the fabrication is complete.

As always, better surface preparation will ensure the best results. We, therefore, recommend applying Rustbuster Weld-Thru Primer to steel that has been prepared to at least the St3 standard with hand or mechanical preparation tools such as wire brushes, abrasive wheels etc., or to a higher standard via blasting. (Read our guide to surface preparation standards for more information.)

Rustbuster Weld-Thru Primer can be applied over steel treated with our Phos-Kleen B rust remover and phosphating solution. Rustbuster has also tested our Weld-Thru Primer with the ‘Enviro-Strip’ body stripping and phosphating process with excellent results.

Supplied as a two-component kit, with a mix ratio of 2:1 by volume: 2 parts component A (hardener) to 1 part component B (zinc paste). Please follow the instructions for the best results.

| Product description | Red two-pack modified zinc silicate pre-fabrication primer. |

| Pack description | 750ml kit covers approx. 10.5m2. Includes 500ml component A and 250ml component B, plus two mixing cups.

1.5ltr kit covers approx. 21m2. Includes 1ltr component A and 500ml component B, plus four mixing cups. 6ltr kit covers approx. 84m2. Includes 4ltr component A and 2ltr component B, plus four mixing cups. |

| Mix ratio | Mix ratio: 2 parts component A (hardener) to 1 part component B (zinc paste). |

| Thinning | Weld-Thru Primer is ready to use once mixed and thinner is not required. |

| Application | Brush or spray. |

| Spraying | Airless spraying uses a 15-23 tip.

Conventional spraying uses a 1-1.5mm nozzle. |

| Pot life | Pot life is the time from mixing the two components together to the point at which the mixed paint is no longer usable. For Weld-Thru Primer, you have 2.5 hours of pot life once mixed at 20c – longer at colder temperatures. |

| Shelf life | We recommend storing upside down in a dry place at around 20c. In these conditions, the product has a shelf life of 12 months. Do not allow it to freeze. |

| Disposal | Allow any waste mix to cure in your mixing cup and throw it away as dry waste. |

| Cleaning | Clean up with standard thinner or gun wash. DO NOT thin Weld-Thru Primer as this will affect the paint cure. |

| Safety | Use in a well-ventilated atmosphere. Use a respirator face mask when spraying or brushing in an enclosed space. Please see the MSDS (material safety data sheet) in our data sheet area.

Wear suitable protective clothing, gloves and eye protection. |